De-Aerators

Overview

The mixing head is designed to mix incoming flows of condensate from the system, flash steam, cold water make-up feed and re-circulation feed. Each inlet connection has an internal sparge which sprays the flow in various directions within the head. These gases are then vented to atmosphere.

The de-aerator head re-circulation connection has an internal spray nozzle to help mixing of the various inlets. GMS can supply the pump re-circulation system as part of the package (contact our sales team for more information).

Design

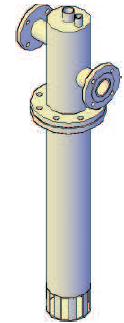

The GMS range of de-aerator units heads comprise of a stainless steel mixing head and a stainless steel immersion tube.

The unit is designed to be maintenance-free with a stainless steel body (wetted parts). Gaskets and all bolting are supplied with the unit.

Thermal Insulation

- Type MA: Consists of 50mm mineral wool with dimpled aluminium cladding. This gives good thermal insulation and a quality finish. For some installations there will be a high risk of damage to the factory fitted insulation. In these instances it is preferable to insulate on site.

Please consult Page 11 of the data book for the details on the standard range of GMS de-aerator heads and immersion tubes.